Introduction

The field of non-destructive testing (NDT) has seen a remarkable advancement with Sciensoria’s latest innovation, the Z-ScopeTL2M21. This cutting-edge instrument offers unparalleled capabilities, empowering professionals to perform precise and reliable assessments across various industries. From electrical contact pads to spot-welds and motor shaft eccentricity, the Z-ScopeTL2M21 sets new standards in performance, portability, and connectivity.

Unleashing the Power of Z-ScopeTL2M21

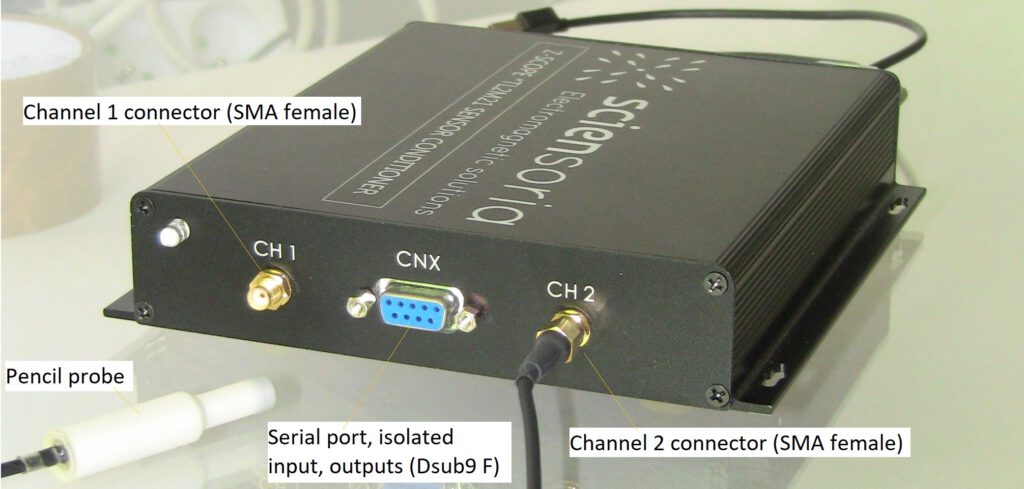

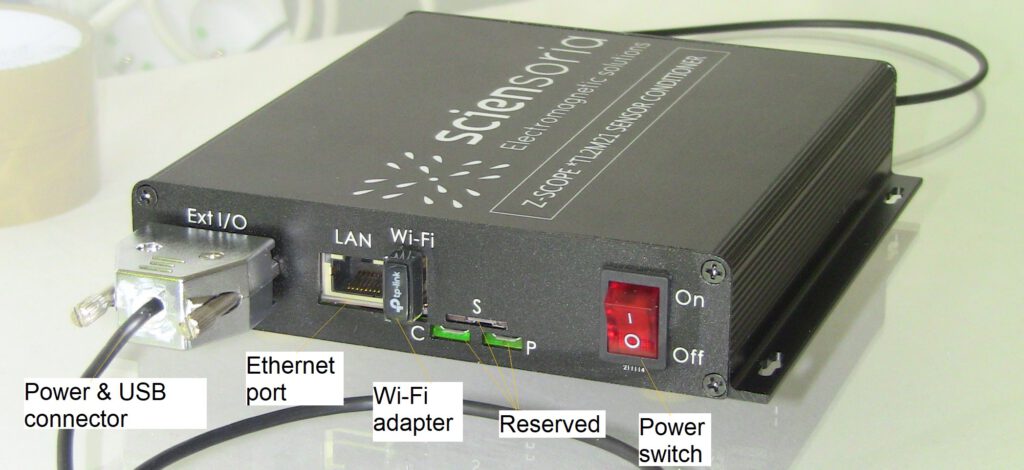

With its compact and lightweight design, the Z-ScopeTL2M21 provides ultimate flexibility, allowing users to work anywhere. Whether connected to a Windows PC or running stand-alone in a production line with a factory PLC, this instrument delivers exceptional performance in any scenario. The incorporation of Wi-Fi connectivity enables installation on moving or inaccessible systems, facilitating data collection from a safe distance.

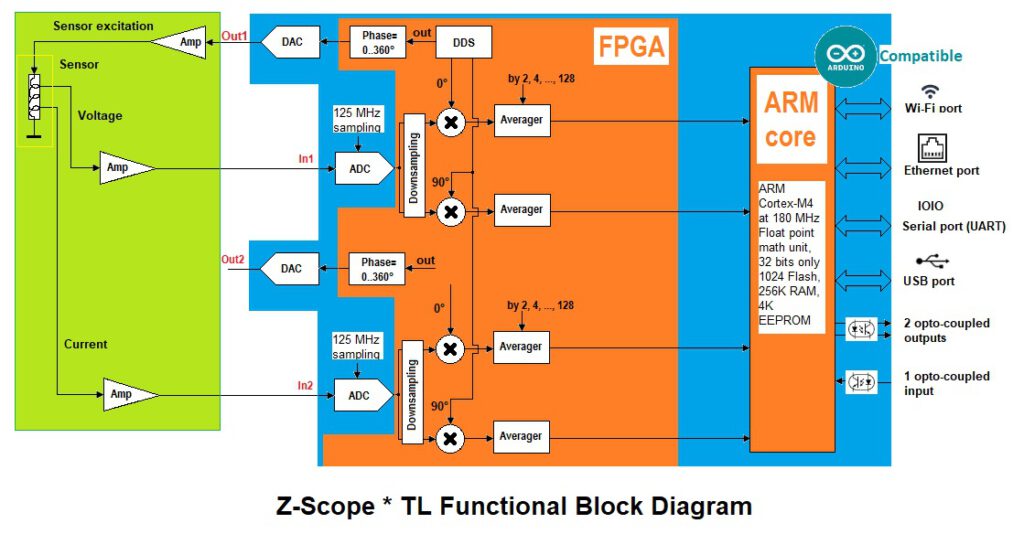

The Z-Scope*TL2M21 Functional Schematic: Empowering User Application Development

The image below illustrates the functional schematic of the Z-ScopeTL2M21, showcasing its internal components and architecture. One of the standout features of this instrument is its compatibility with the Arduino platform. With its Arduino-compatible feature, users can effortlessly and rapidly develop their own tailored applications, significantly reducing development time compared to other platforms. The Z-ScopeTL2M21 embraces an open structure, offering application developers and inventors the freedom to explore and innovate. Unleash your creativity and harness the full potential of the Z-Scope*TL2M21 to bring your unique ideas to life.

The Z-Scope*TL2M21 Functional Schematic

Applications and Benefits

The Z-Scope*TL2M21 proves its worth across a range of critical applications. In the non-destructive testing of electrical contact pads, the instrument ensures the presence of solder layers and verifies correct pad orientation, enhancing circuit breaker performance. Moreover, the eddy current technique enables quality testing of spot-welds, a popular application in multiple industries.

The instrument’s versatility extends to monitoring the eccentricity of motor shafts. With its high data capture rate, the Z-Scope*TL2M21 excels at measuring eccentricity, even at high engine speeds. This feature enables efficient maintenance and optimal motor performance.

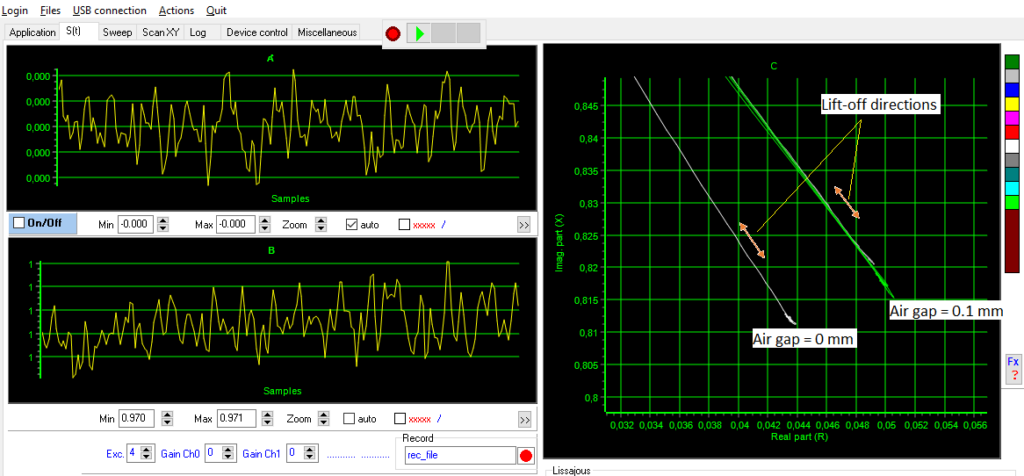

Detecting Air Gap Between Two Aluminum Sheets: A Sample Application

In this sample application, the goal is to detect the presence of an air gap between two assembled aluminum sheets. The specifications of the sheets and the dimensions of the air gap are as follows:

Sheet 1:

- Thickness: 0.5 mm

- Conductivity: 16 MS/m

Sheet 2:

- Thickness: 0.8 mm

- Conductivity: 19 MS/m

Air Gap: 90 µm

The objective is to utilize non-destructive testing techniques, such as the eddy current method, to accurately identify and measure the air gap between these two aluminum sheets. By employing the appropriate instruments, including Sciensoria’s Z-Scope*TL2M21, precise and reliable detection of the air gap can be achieved, ensuring the quality and integrity of the assembled components.

The image below illustrates the process of obtaining the airgap signature using the advanced eddy current non-destructive device, Z-Scope*TL2M21.

Measurement of Air Gap Using Eddy Current Signatures

Spot-Weld Quality Assurance: Non-Destructive Testing with Eddy Current Technique

See the YouTube video below, which demonstrates the utilization of a small eddy current probe to assess the quality of spot-welds. This widely popular application is extensively employed across various industries. The video highlights the effectiveness of the technique in ensuring the integrity and reliability of spot-welded joints.

Non-Destructive Testing of Electrical Contact Pads (Métalor SA, Switzerland, https://metalor.com/)

Below is a video clip showcasing the non-destructive testing of electrical contact pads commonly used in circuit breakers. An electrical contact pad has two sides: one side ensures the opening and closing of the electrical circuit and is specially treated to withstand electric arcs. The other face is coated with a layer of solder alloy, intended for soldering to the internal circuit of the circuit breaker.

The non-destructive test using eddy currents ensures the presence of the solder layer and verifies the correct orientation of the pads along the welding line.

This application can also be applied to control the thickness of plating/tinning on metals or the metallization of plastic or carbon composites.

Connectivity and Software

The Z-Scope*TL2M21 offers flexible connectivity options, including USB and Wi-Fi interfaces, ensuring seamless data transfer and integration with other systems. The instrument’s on-board microprocessor performs all necessary signal processing for stand-alone operations, while optional logic input/output interfaces enhance compatibility with industrial environments.

Accompanied by the WinEC(tm) software, the Z-Scope*TL2M21 provides a user-friendly interface for visualization, analysis, and calibration. This comprehensive software empowers users to maximize the potential of the instrument, whether operating in connected or stand-alone mode.

Conclusion

Sciensoria’s Z-Scope*TL2M21 revolutionizes non-destructive testing, offering advanced features, portability, and connectivity. From assessing electrical contact pads and spot-welds to monitoring motor shaft eccentricity, this instrument exceeds expectations in precision and reliability. To learn more and request a quotation, reach out to Sciensoria via e-mail at info@sciensoria.fr or by using the contact form on our website https://www.sciensoria.fr/en/contact-us/.

Unlock the potential of the Z-Scope*TL2M21 and experience the future of non-destructive testing today.

(*TL2M21 refers to the model variant and is subject to change.)