Conducsens™ – A Multi-Parameter Testing Tool for Flat and Curved Geometries

Conducsens™ – A Multi-Parameter Testing Tool for Flat and Curved Geometries

Conducsens™ is an expert system for non-destructive eddy current testing. It provides all the essential functions required for this type of inspection, including:

-

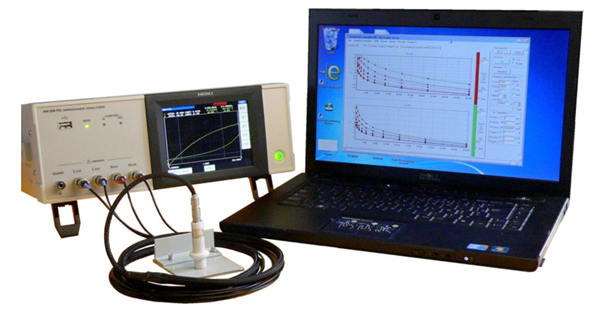

Measurement of sensor impedance in single- or multi-frequency mode. The applicable frequency range depends on the model of impedance analyzer used. Compatible models include:

– Hioki IM3570, IM3536, IM3533-01

– Keysight 4980A

– Hewlett-Packard HP4192A -

Simulation of sensor impedance

-

Impedance inversion in single- and multi-frequency modes. This function calculates the target parameters (e.g., thickness, conductivity) from the impedance values measured by the analyzer.

Conducsens™ is frequently used in highly challenging applications, including:

-

Thickness measurement of enclosed metal components made from various metals that are not predetermined. In such cases, both the thickness and electrical conductivity of the material are measured simultaneously.

-

Thickness measurement of thin nickel sheets, which are magnetic materials.

-

Thickness measurement of turbine components manufactured via 3D printing.

-

Electrical conductivity measurement of low-conductivity materials, such as graphite or carbon fiber reinforced polymers (CFRP).

The Conducsens™ system has been successfully adopted by several prestigious companies, including:

-

Alstom Power (now General Electric Power) — for measuring the wall thickness of 3D-printed turbine blades.

-

Airbus Innovation Works — for measuring the electrical conductivity of CFRP (carbon fiber reinforced plastic).

-

Surys — for measuring the thickness of high-precision electro-deposited nickel plates.

-

Schneider Electric — for sorting magnetic stainless steels.

-

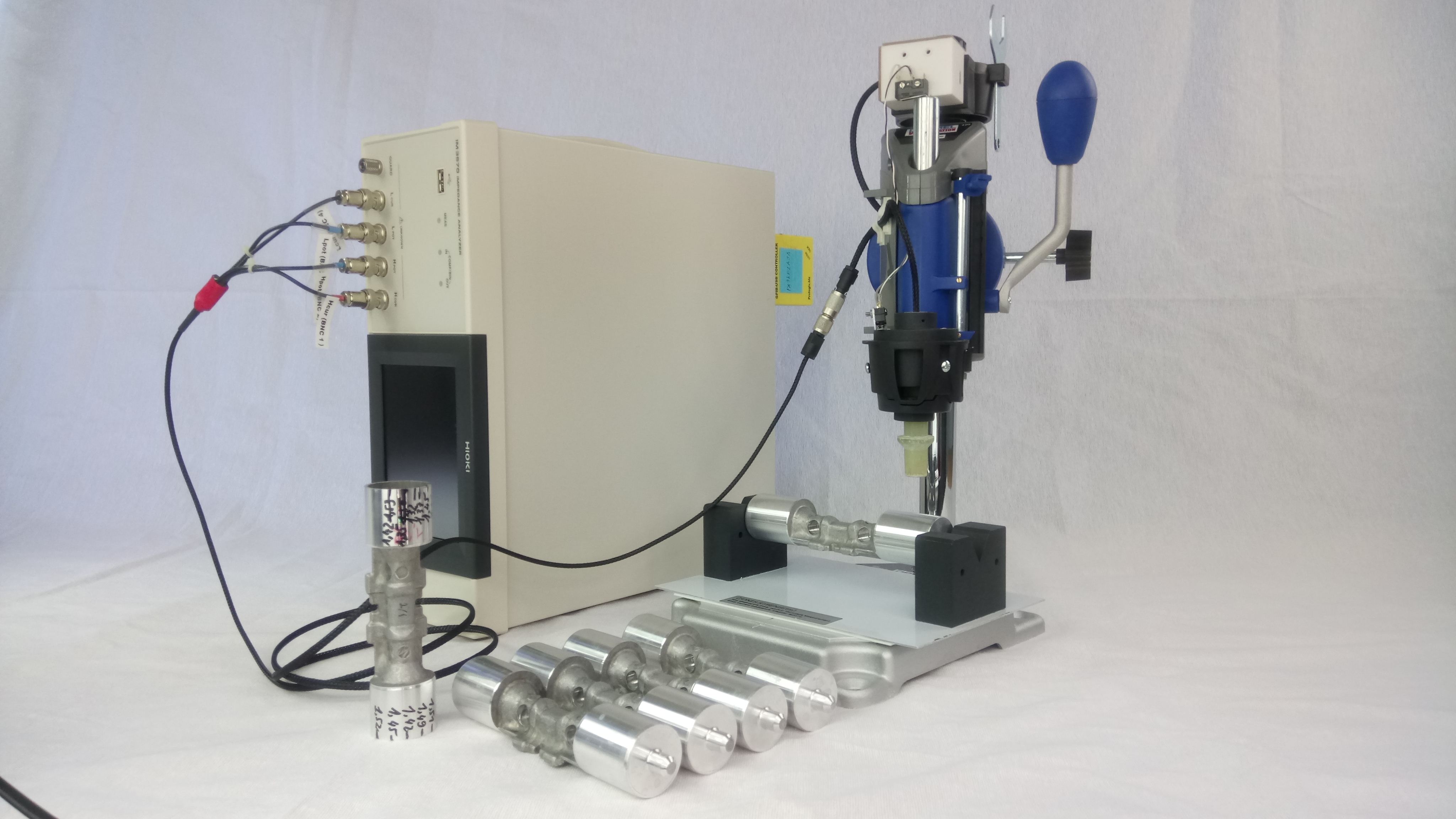

Mahle — for measuring the wall thickness of car air-conditioner pistons.

Two Conducsens™ systems from Sciensoria inspected over one million pistons in just six months, ensuring wall thickness consistency within 0.01 mm for a nominal thickness of 1.5 mm.

The Conducsens™ system is an ideal complement to ultrasonic thickness gauges. While ultrasonic instruments are highly effective for thicker walls, their accuracy diminishes with thin walls. This is because, in thin materials, the ultrasonic echo returns very quickly after bouncing off the opposite surface, making it difficult for the electronics to precisely measure the travel time.

In contrast, the eddy current method excels at measuring thin walls, though its accuracy gradually decreases as wall thickness increases. As a result, both methods are highly complementary and can be used together to achieve optimal measurement performance across a wide range of thicknesses.

The eddy current measurement range typically spans from a few micrometers (µm) up to approximately 10 mm, depending on the material’s electrical conductivity. For instance, in the case of aluminum, the effective range is approximately 10 µm to 3 mm.

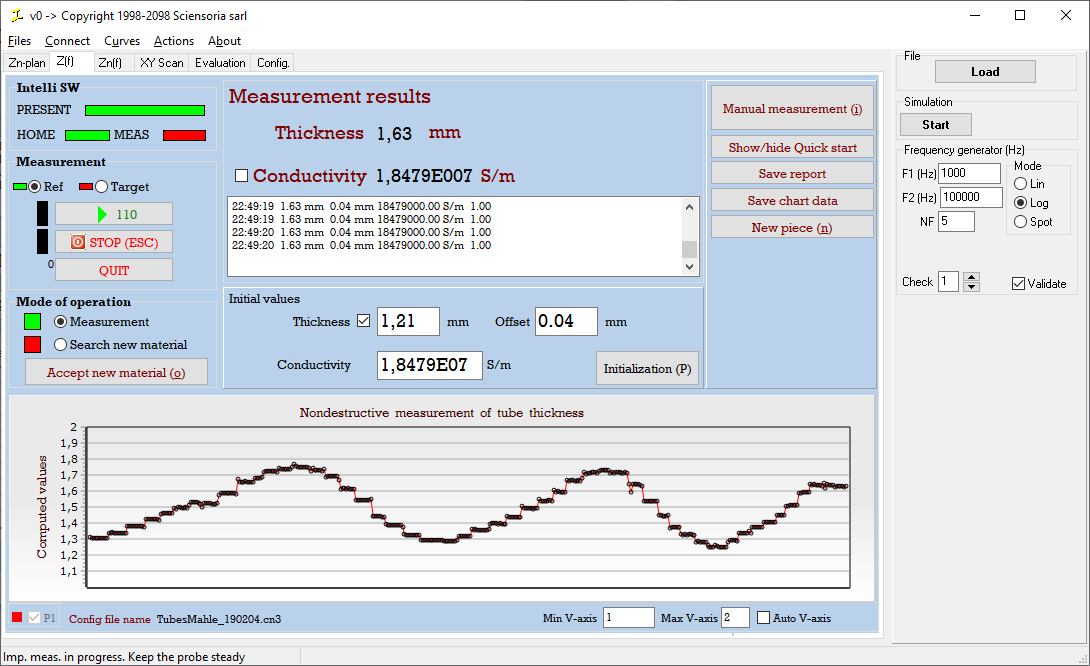

Graphical user interface of Conducsens™ for measurement of aluminum piston wall thickness destined to

Mahle (German automotive supplier)

Latest news: Électricité de France (EDF) has acquired a Conducsens™ system to study its materials, measuring tube thickness, electrical conductivity, and magnetic permeability.

Related topics: