Insulating materials are becoming more and more important in the modern world. The discovery of electricity, the need for materials that are easy to form, resistant to water, inexpensive, lighter than metals, etc. have pushed engineers to develop many high-performance insulating materials.

Figure 1 – Insulating materials

Metals are conductors and can therefore be controlled by the eddy current method. Not the insulators. However, this gap has just been filled by Sciensoria’s mastery of a new technique: high frequency wave emission.

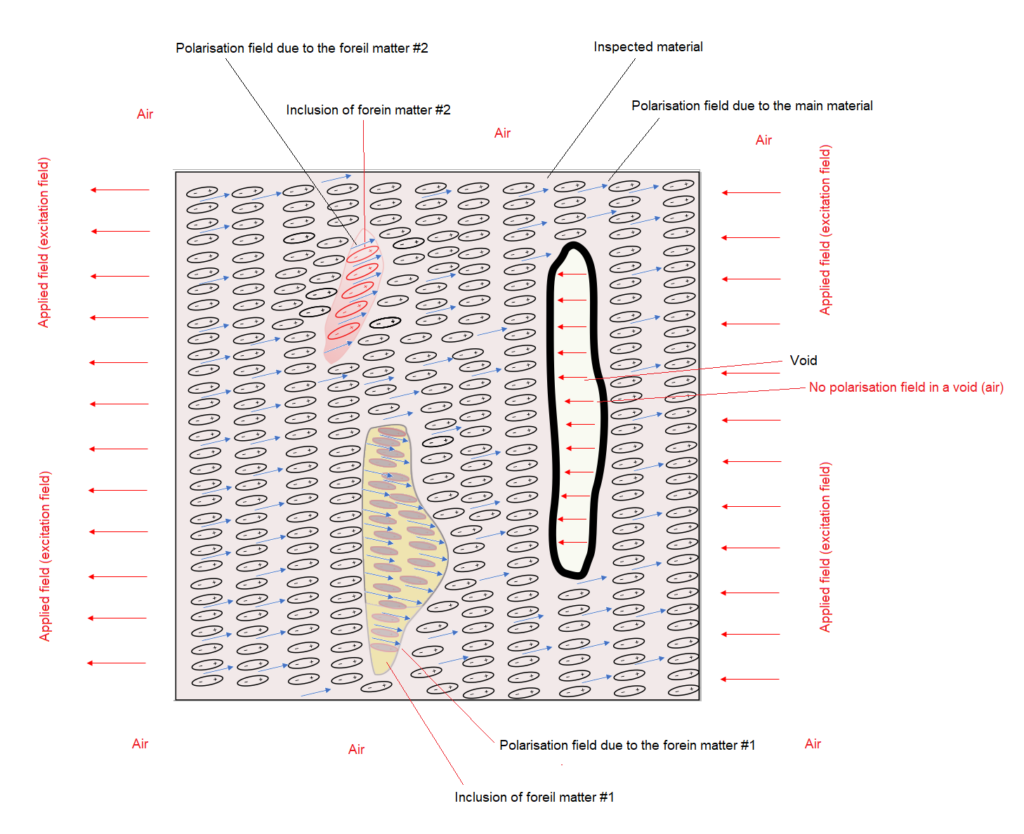

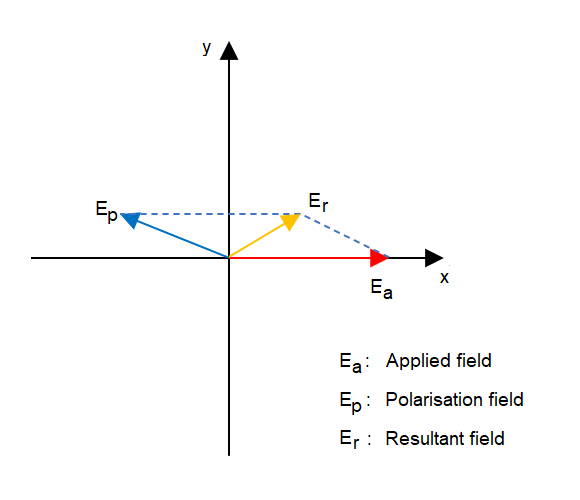

The principle of operation of this technique is as follows: the probe applies a high frequency electric field to the material to be tested. Inside the material, a phenomenon of polarization occurs: molecules reorganize themselves and create an electric polarization field which tends to oppose the applied electric field. By capturing the global electric field which is the vector sum of the applied and polarization fields, it is possible to determine the state of the material under test.

When there are defects in the material under test (voids, inclusions of unwanted foreign matter, penetration of moisture or water), the local polarization fields are different from the general polarization field. It is therefore possible to observe local variations in the overall electric field if a small field sensor is used to scan the surface of the material under test.

Figure 2 – Illustration of an insulator with defects and the distribution of applied electric fields and polarization in an insulating material

Figure 3 – The global field is the vector sum of the applied and polarization fields

If there are any defects inside the material under test such as voids, delamination, inclusion of foreign matter, ingress of water or other liquids, the probe can detect them. It can also measure the thickness of insulation sheets.

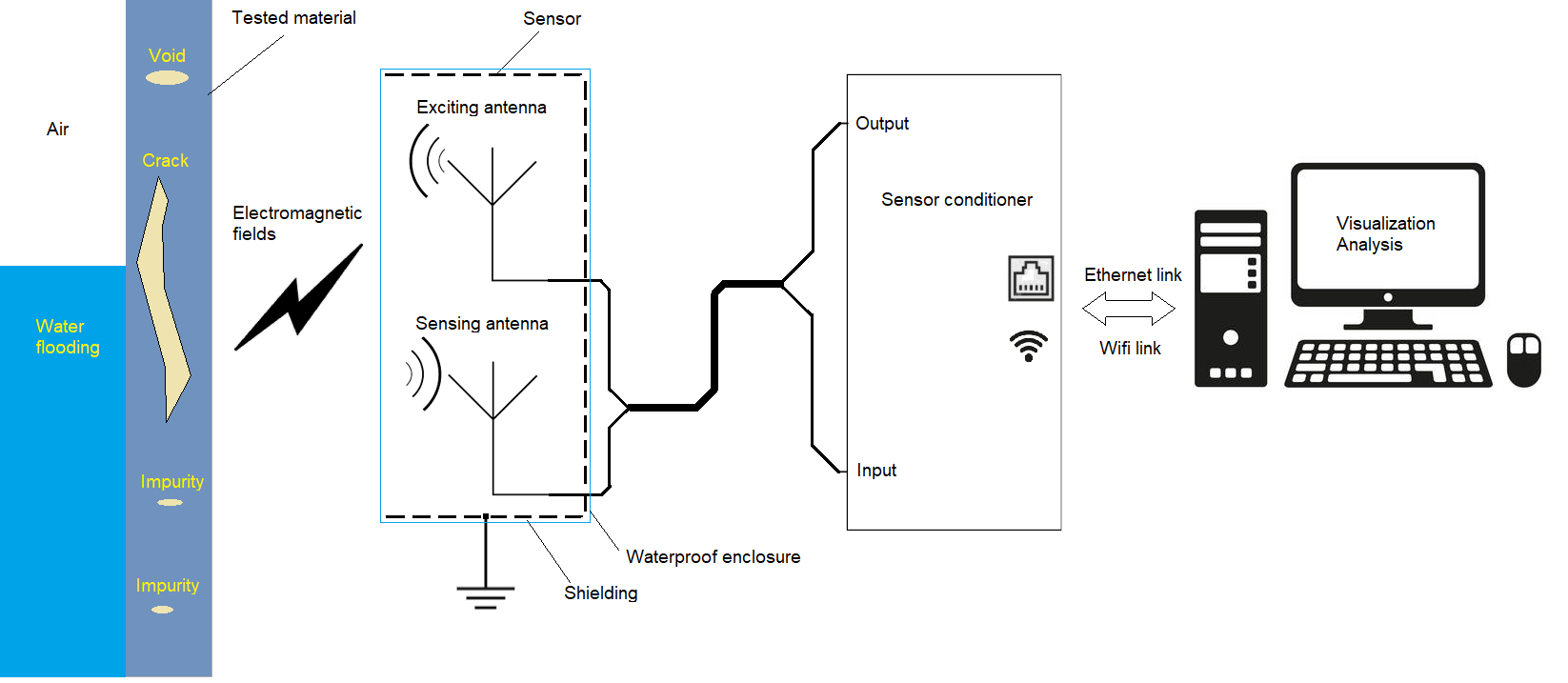

A non-destructive control system for insulating materials comprises an electromagnetic sensor, an on-board network analyzer and an Ethernet or Wifi link with a computer which allows the signals to be visualized and analyzed.

Figure 4 – Synoptic of a nondestructive system for nondestructive testing of insulating materials

The electromagnetic sensor is composed of specially positioned antennas, the whole is shielded and encapsulated in an insulating material.

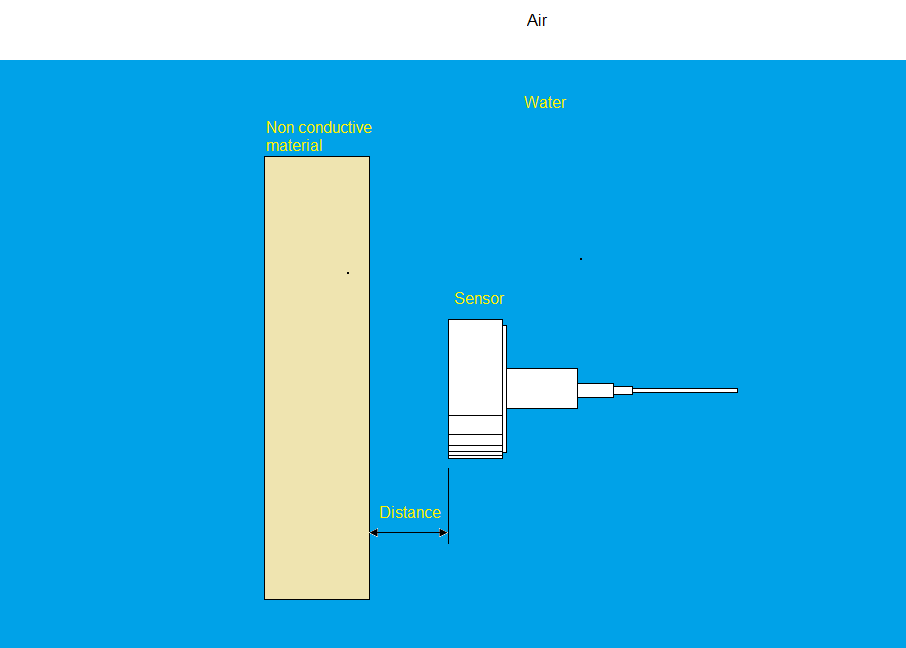

The sensor can work in air as well as in water.

This technique therefore opens up a very wide field of application and meets many unresolved needs. Here are some examples of application of this technique:

- Measurement of the thickness of insulating materials such as plates, sheets or thin layers

- Measurement of the coating thickness of insulating material (ceramic, plastic, etc.)

- Detection of defects (voids, delamination, detachment, inclusion of foreign bodies, penetration of water or other liquids)

- Control of the water impregnation extent in concrete

- Distance measurement between a sensor and a body made of insulating material, even immersed in water

- Detection of flooding of immersed structures, such as flexible risers used in offshore oil and gas fields. In this case, flexible risers need to be monitored carefully in order to determine if there is water under their sheath. In case of confirmed flooding, the risers have to be replaced, otherwise they can break and collapse, causing oil or gas leak, fire, pollution, etc.

Figure 5 – Measuring the distance to an object made of non-conductive material in water

Please do not hesitate to contact us at info@sciensoria.fr for more details.