The Z-Scope * vn2k20 USB Eddy Current Non-Destructive Testing Instrument is a valuable tool for materials testing!

Sciensoria’s new eddy current nondestructive tester is both lightweight (400 g) and powerful. It is powered by a USB port and has a frequency range of up to 40 MHz, as well as 2 multiplexed input channels for 2 probes. With a data rate of up to 40 measurements per second through a USB connection, this new model is well-suited for a wide range of applications. The Z-Scope*vn2k20 is capable of measuring electrical conductivity, thickness of metal objects, thickness or electrical conductivity of conductive coating on insulators, detecting cracks or defects on static or slow-moving objects, or manual mode at slow speeds, as well as slow displacement and position measurement on slow-moving objects.

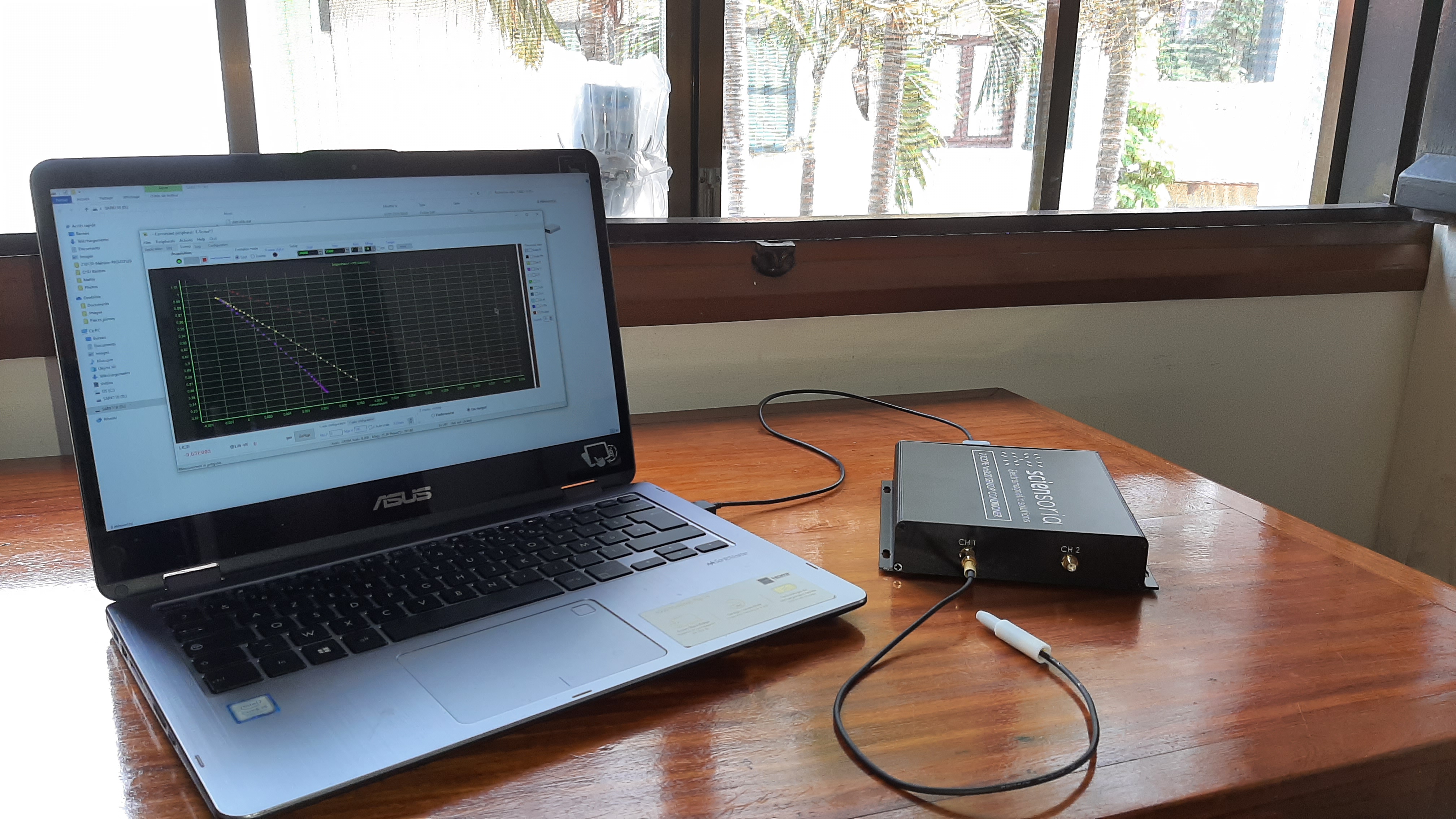

Z-Scope*vn2k20 – Front view

Z-Scope*vn2k20 – Rear view

Work comfortably with the Z-Scope * vn2k20 anywhere thanks to its small size, low weight and USB connectivity

Technical specifications

- Excitation frequency range: 10 kHz – 40 MHz

- Probe connection: absolute type (single coil)

- Number of input channels: 2

- Embedded microprocessor: STM32F-103. The on-board microprocessor performs all the signal processing operations required for stand-alone mode (factory mode)

- Logic input / output: 1 opto-coupled input, 2 opto-coupled output (24V compatible)

- Interface: USB

- Windows Software: WinEC ™ software allows the user to view, analyze, and calibrate the system for measurement in online or standalone mode

- Weight: 400 g

Examples of application

Electrical conductivity measurement of metallic coating deposited on plastic substrate

The Z-Scope * vn2k20 device was used to measure the electrical conductivity of a metallic coating (aluminum, copper, titanium, stainless steel, etc.) deposited on a high performance plastic substrate.

The Cold Spray technique is used to deposit metal on insulating substrates. The image on the video below shows possible applications: electromagnetic shielding, anti-erosion, PCB manufacturing, etc.

Controlling the electrical conductivity of the deposited metal is essential because the metal projected onto the surface no longer has the same electrical conductivity as the original metal. The result of the control will be used to adjust the process parameters.

The eddy current probe has a control spot that is only 3mm in diameter. It allows a very fine check of the deposited metal surface. With an inspection speed of 40 measurements per second, an entire surface can be inspected in a very short time.

The video below shows the application in detail. The application was carried out on behalf of ICAR-CM2T, a materials study laboratory located in Lorraine.